|

|||||||

|

|||||||

|

GPD Running Conditions

1. Power Source: Voltage - 230V, frequency - 60Hz.

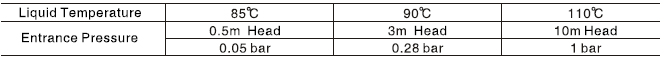

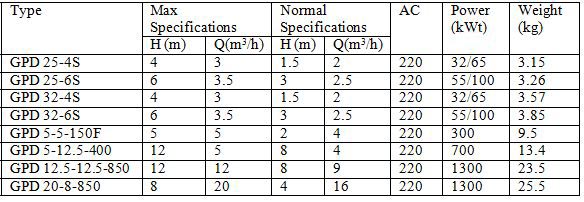

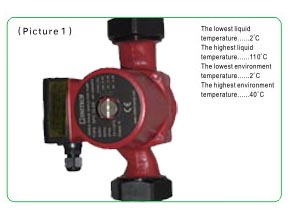

5. To avoid NHP damage to the pump bearing, pump should be maintained according to the following minimum pressure standards:2. Maximum pressure of the system: No more than 1.0MPa.. 3. Transmission Fluid: Lean, clean, non-corrosive and non-explosive liquids, and without any solid particles, fibers or mineral oil, Pump absolutely must not be used to transport flammable liquids such as diesel and petrol. 4. The pumps should work under air temperature of environment rang of 0°C~40°C, water temperature rang of 2°C ~110°C ,except the automatic pump. For pumps with power below 250W, the inlet minimum water pressure should be maintained as following:  GPD series pump types and specifications:

Character of sturcture:

1.Structure: The product is made up of a pump and a single-phase shield motor. The pump is made up of impeller. The body of the pump and motor consists of stator, rotor, shield cover and deflating bolt. 2.Seal:The pump isn't sealed with machinery sealing. The stator and rotor of motor are sealed with stainless steal cover. Other parts are all sealed with heat-resisting rubber facing ring. so that there is no leakage. 3.Lubricate: The water between the stator and the rotor can lubricate and cool the motor as the lubricant and coolant. 4.Motor class is H insulation and equipped with thermal protection. The choice of the product:

The users can choose the different type according to the flow, head in the performance curve.

The inlet and outlet of GPD series including the screw connection and the flange connection. The inlet and outlet of GPD series adopts flange connection. lf the dimension of the inlet and outlet or the shape you need is different from what shows in the catalog. We can design a pump for you specially. Usually, the pump body material of the GPD circulating pump adopts cast iron but we can adopt the brass as well. When the transport medium is clean water which is in the normal temperature, we suggest you to use cast iron. When it is used in the heating pipeline system which is underground. We suggest that the brass or bronze be adopted as the pump body. When it is used in cycle of life hot water. You can use stainless steel,brass or bronze. Attention:

Pump installation must ensure the motor shaft in horizontal.

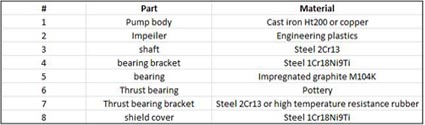

Structural Diagram:

Every homeowner in the United States has been faced with waiting for hot water at his or her shower or faucet. It is frustrating, inconvenient and it wastes thousands of gallons per household every year. Wouldn't it be nice if you could turn on a shower and walk right in? Is it a novel thought with today's know-how and new technology? Not really. Everyone should know that water recirculation systems are available for new homes, but must be specified by the homebuyer. The way that Hot Water Recirculation works is that all the faucets, showers and water appliances are linked (in series) by the piping in a continuous line. At the last faucet or water fixture, a return pipe is installed that goes back to the water heater. Also, at the water heater, a circulator pump, check valve and control system are installed. When the system calls for the water to be heated, the circulator pump turns on and moves the water through the water heater, through each faucet, shower, water appliance, etc. and back through the return water pipe. This system becomes one continuous pipe loop with available hot water when you want it. There are several benefits of having a Hot Water Recirculation system installed in your home. Besides adding value to the home, comfort and convenience are the primary reasons for installing a Hot Water Recirculation system. It provides the comfort of instant hot water, without the inconvenience of waiting and the unnecessary waste of water. You must remember that we pay for water being supplied to the home, heated and drained. |

|

|